When defining an inspection strategy for your manufacturing processes there are many factors that need to be considered. As well there are many products that seem to have solutions to your inspection requirements, how do you make the decision of which system to use? How do you determine the viability of manual inspection, of template/comparative vs. measurement based AOI, what resolution to use, which cameras, what data outputs are required, do you need measurement data, attribute data or both.

There are many questions that can be asked and the goal of this paper is to detail what variables are important vs. those that can confuse the AOI selection process. For this purpose this paper will discuss the top five variables that can ensure a successful AOI deployment in your manufacturing processes.

Figure 1 – Structural DPMO Rates

♦ 1. Ask yourself, why are you purchasing an AOI system? Defect coverage?

The first question you should ask yourself is why you are purchasing AOI? Hopefully the answer is to detect defects. From previously experiences some users even leave this out from a system evaluation.

When you look at defect coverage do you know your process and the defects that can arise during SMT manufacturing; solder defects (tombstones, opens, solder amounts etc), presence/absence, component measurement data, wrong components etc. This knowledge and how you use this data is important to making an inspection decision. There are many industry bodies that can help you to determine yields and possible defects. As a guide, based on internal studies and industry standards, DMPO (Defects Per Million Opportunities) rates are defined in table 1 and 2, and can be used as a base line for defect detection requirements.

When considering defection inspection capabilities there are a number of items to consider;

Figure 2 – Typical Process Defect DPMO Rates

♦ i, Inspection techniques, capabilities of template matching vs. measurement based AOI platforms.

There are two basic techniques used by AOI systems; template based comparison systems and rules based measurements systems. The main difference is measurements. For example a rules based system will measure the width, length and position of a component then from this position measure the actual amount of solder on each pin (referenced to component position), then perform OCV or OVR dependant on component marking. The component body measurements provide the capability to find the correct component and the solder measurements will provide the exact percentage of solder between the component and the pad. Whereas a template based system will look for presence absence of the component and compare the joint to a known good joint, which can lead to a higher volume of false calls. When, as in most manufacturing scenarios, defects will follow the DPMO rates shown in Table 2 and you will have solder defects, tombstones, and opens it is important to select a system that has the capabilities to inspect for solder.

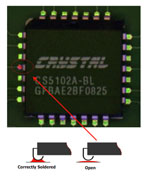

Another question that is normally discussed is do we need to use angled cameras to locate defects. There are many arguments to this, but generally angled cameras are complex to calibrate and can be significantly affected by board warp. If you understand the reflow process, a single telecentric camera system can provide the same defect coverage as an angled camera without calibration or warp issues. Figure 1 shows a real life example where the left center pin (pin 25) is open. On a single, telecentric camera system using tri-color lighting (Tri-Color technologies use angled lighting vs. angled cameras) the defect is easily visible by inspecting the changing reflow profile. As you see in the example the failing joint shows up red from the red 45 degree lighting vs. the high green lighting which shows good joints.

Figure 3 – Jlead defect on a single camera system using Quad Color Lighting

♦ ii, Detection Toolbox, what tools/algorithms are available to detect defects.

As technology changes are a constant in our industry, it is important to understand the flexibility of the inspection tools and future capabilities of the AOI system. Is the system always going to be post reflow? Will you ever look to put the system in a new position in the line? What technologies are you building today and what is your future roadmap for manufacturing?

Some AOI systems are purely focused at a single task i.e. Paste, Pre-Reflow, Post Reflow or Post Wave. More experienced AOI suppliers will provide solutions that cover all aspects of the manufacturing line in the same system, provide integrated 2D/3D technologies, while also providing capabilities for microelectronics and semiconductor inspection. If you are looking at maximizing the ROI (return on investment) for your AOI purchase, process position flexibility and inspection capabilities of the system are key to the success of your investment. As an example an experienced AOI supplier such as can provide extensive capabilities (shown in Figure 2), which allow for many different inspection scenarios beyond basic SMT inspection.

Figure 4 – Inspection Techniques

♦ iii, False call rates and how these affect defect coverage.

For fault coverage one of the key items that affects the overall efficiency of defect detection is the false fail rate of a system. Simply put the more false fails you pass on to a repair operator for validation the more real defects get missed. A major study by Solectron presented at IPC showed that when false fails increased excessively, i.e. above 3000 ppmJ, an inexperienced operator could make <5% correct calls, while an experienced operators correct call rate still fell by over 50%.

Ensuring low false call rates can be a key aspect of a successful AOI implementation, increasing overall quality while reducing costs.

Figure 5 – The Benefits of low fails fail rates

♦ iv, What is your defect coverage, how do I get an accurate inspection coverage report.

Whereas many electrical test platforms such as ICT and Flying probers provide accurate reports on defect coverage most AOI platforms do not have the ability to provide this required feature. When you have an inspection routine in place how do you know it is actually finding defects? A few experienced vendors can provide this information, with the most capable AOI vendors providing validated defect coverage for all defects detected by the AOI system.

This is an important point that should not be ignored, their may be items on the product that may not be inspectable, knowing this will allow you to better plan your overall test and inspection strategy.

♦ 2. Improving your process and providing process feedback

Figure 6 – The Benefits of Parametric data from a rules based AOI system

Beyond catching defects what other aspects of an inspection system are important to manufacturing processes. Do you monitor how is your process changing? Can you predicatively highlight issues that will cause defects? If you are focused at improving your manufacturing processes, you will need variable data (measurements) vs. attribute data (pass/fail). If you are only looking at end of line defect data the attribute data produced by template/comparative systems may be adequate, if you are looking at understanding the process and correcting issues, access to parametric measurement data will allow for complete process control.

Figure 4 shows a simple example of a placement head going out of calibration. The top part of the graph shows the measurement information from a rules based AOI system and the control limits for the process. The lower part of the chart shows the attribute data from a non-measurement based AOI platform. The measurement system can provide data in real- time that can highlight the components placement going out of control far before it fails a pass fail limit is met. The benefits of process monitoring and SPC are well known and if these techniques are to be implemented in your process, the ability of the AOI system to measure placement and solder amounts will again increase the value of the AOI system.

♦ 3. Programming time

How fast is fast enough? This is a question the user of the AOI system will have to answer, but there are two factors to consider, first program development time vs. ongoing program support.

When having a demo of an AOI system most companies will have a program running in 1-2 hours or even less. However, check to see of this is realistic vs. how you will be using the system in your manufacturing process. Its important to look at programming (initial programming) and program support (program debug on new batches of products) times for the overall usage of the system and try not focus on the first demo program.

When using a template/comparative based system ask the question:

i. Is the program inspecting all defect types including solder?

ii. What is the false call rate, or on-going program debug required for the next batch of boards? How will this affect fault coverage?

When looking at rules based systems consider:

i, Is the system library based, if so how much does the use of the library decrease programming times over the lifespan of the AOI system?

ii, If we use rules based systems false fails will be lower, and will require less program support over time.

♦4. Stability, Support and MTBF

Will the AOI company be there to support you? Where does the company have support staff? Has the system been designed to provide high MTBF’s and reliability?

As recent events have shown us, large corporation have unhealthy focus PBIT (Profit Before Interest and Tax) numbers, plus they have high overheads and little focus on a single business. Even if a group is profitable, this has shown that it may not be safe. As such we have seen the exit of multiple major players from the AOI market that many would have described as stable entities that would not leave this business. In addition, some AOI companies have left the market a number of times, coming back under new ownership. This has left many customers with unsupported products with no path forward, and little value left in their investment.

There are a few companies whose sole businesses are focused on AOI. These companies have to providing best in class solutions to their customers; provide the best support, products, while keeping on the leading edge of technology. As AOI is their main and only focus, success in this industry is directly affect the success of their business. If the AOI company has this focus, has proven longevity and technology leadership, this will be a leading indicator that they are here to stay the course.

When it comes to reliability, MTBF is key. Look at the systems components, manufacturing practices used to build the system and the materials used. Does the system use a start stop motion technique or does the system using a linear motion system. For example a linear motion system will provide far greater reliability over time.

Applications and hardware support is important when running in any manufacturing environment. As your staff and personnel change, does the AOI vendor the resources to support you? Does the company have direct applications and hardware support engineers on a worldwide basis? Are those engineers located a reasonable distance from your facility and fully trained. These are important traits that vary greatly across many AOI manufacturers, and could affect your ability to be successful in the longer term.

♦ 5. Resolution and Throughput

Another common mistake made in an AOI evaluation is the focus on camera size, i.e. it is normally presumed that the larger the number on megapixels the camera has provides better performance. This is not always true; camera sensitivity (how fast you can take an image), resolution at the given FOV, what motion system is used (on a start stop system, is their extra time for the stage to stabilize before an image is captured), and the overall throughput at the same resolution are the aspects that need to be evaluated.

For example a system using a 1.4mp, high sensitivity camera, providing a resolution of 12um could have a throughput of 7sq in/s where a system with a low sensitivity 3mp camera only provides a resolution of 25um at 7sq/in per second. Design traits that will slow throughput include vibration from a high-speed move and stop, low sensitivity cameras, stage speed and overall FOV.

There are many factors that can affect throughput, but a defined resolution is required to detect defects, as a guide table 3 defines the typical resolutions required for inspection of the common component sizes. Understanding resolution vs. throughput will allow you to make a more informed AOI decision.

♦ Conclusion

Don’t make the common mistake and focus your evaluation on a single aspect of an AOI system. Megapixels alone are not important, programming times in a demonstration can be deceiving, and don’t lose focus on your real need for AOI.

Defect coverage, manufacturing strategy flexibility, the use of measurement data, throughput, company stability, system reliability, programming and on-going program support times all need to be judged equally in addition to the over all purchase cost of a system.

Defect coverage should always be the first reason for using any inspection platform. If you understand your manufacturing process and focus on the defects generated in your process the AOI system will always provide you with the maximum value and ROI, while increasing your overall quality.